Overview:

The security of a gun safe is determined by the quality of its features. Each component of a gun safe is designed to help deter the event of an attack, break in,

fire, or any other unfortunate event.

Hardplate:

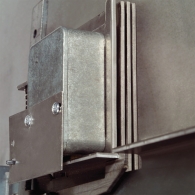

A hardplate is a hardened piece of steel that sits between the safe door and the lock with the purpose of protecting the lock from drilling and punching. A common form of attack occurs where the burglar will smash the dial or electronic lock off of the face of the safe and use a hammer and a metal rod or screw driver to punch the lock through the interior allowing the bolts to release. The hardplate protects the lock from this punch attack keeping your safe secure. There are 3 common types of hardplates including case-hardened mild steel, ball bearing and diamond hardplate.

-

Case-Hardened Mild Steel: This is the simplest style of hardplate out of the three and is just a thick piece of hardened steel. It takes much longer to drill than standard steel but is also the weakest style of hardplate. You’ll find this style on lower end UL approved safes. Companies like Liberty Safe will often add two or three layers of this type of hardplate to beef it up even more.

Case-Hardened Mild Steel: This is the simplest style of hardplate out of the three and is just a thick piece of hardened steel. It takes much longer to drill than standard steel but is also the weakest style of hardplate. You’ll find this style on lower end UL approved safes. Companies like Liberty Safe will often add two or three layers of this type of hardplate to beef it up even more. -

Ball-Bearing: Most commonly used on high-end Liberty Safes, a ball-bearing hardplate utilizes uses tons of tiny metal balls that cause drills to either snap or continue spinning for ever. This style is very effective in protecting the lock from drill attacks and is a nightmare for locksmiths to get the safes open through this method.

Ball-Bearing: Most commonly used on high-end Liberty Safes, a ball-bearing hardplate utilizes uses tons of tiny metal balls that cause drills to either snap or continue spinning for ever. This style is very effective in protecting the lock from drill attacks and is a nightmare for locksmiths to get the safes open through this method. -

Diamond-Embedded Armor Plate: Industrial diamond is bonded to a tungsten steel alloy hardplate and diamond is harder than either a cobalt or carbide drill. When drilling is attempted the diamond removes the cutting edge from a drill – thus dulling the drill bit to where it will not cut.

Diamond-Embedded Armor Plate: Industrial diamond is bonded to a tungsten steel alloy hardplate and diamond is harder than either a cobalt or carbide drill. When drilling is attempted the diamond removes the cutting edge from a drill – thus dulling the drill bit to where it will not cut.

Relocker:

A relocker is a device that is attached to the lock on the inside of the safe door that activates and locks the safe’s boltwork in place when triggered by heat or force. For example, if a burglar is able to drill through the hardplate and punch the lock through, a pin will drop in the lock’s place preventing the boltwork from releasing. There are several types of relockers that serve different purposes.

- Glass Relocker: With this type of relocker, tempered glass is placed between the inner door’s steel plate and the lock. If the glass is broken by drilling or punching, a secondary mechanical system is released to lock the boltwork in place

- Heat Relocker: Locks made by S&G have an insert in the lock body that melts at low temperatures and locks the boltwork in place during a heat attack where a thief will use a blow torch in an attempt to melt the lock.

- Mechanical Relocker: This type of relocker is by far the most common and typically mounted on the back of the safe’s lock. If the lock is forced off, a pin will drop and prevent the boltwork from releasing

- Remote Relocker: This system is usually attached to a mechanical or glass relocker but is located in a random location not near the lock. Now that relockers are more commonly known by burglars, it adds an additional layer of security as it is now placed in a unique spot and not a commonly known area.

Locks:

There are four main types of locks used in the industry today: Redundant, mechanical, electronic and key. All three have their advantages and disadvantages and it’s up to you to decide which one fits you best. New within the last 3 years are locks that have both electronic access and a mechanical override called a redundant lock. These types of locks are the most effective as you can never get locked out of your safe, as long as you don’t forget the combination that is.

- Mechanical Locks: Mechanical Dial locks have been around for over a hundred years and typically use 3 or 4-wheel combinations. The main weakness of this style of locks is it’s speed. It takes well over a minute to dial in the combination and when you need frequent access to your safe, this is typically the worst option. The major benefit in theses locks is the reliability. You’ll never have to worry about your batteries dying or any type of electronic failure. These locks perform reliably for damn near ever.

- Electronic Locks: A major innovation to an ancient industry, electronic locks provide speed and higher security as there are more possible combinations to enter than a mechanical lock. The major disadvantage is reliability and batteries. The lock is the most important part of the safe, without it, you can’t get in and unfortunately there are certain manufacturers like Kaba and Securam that use cheap components causing more frequent failures in safes. Considering a drill job costs near $400, it’s very important to buy a good quality electronic lock or just go with a redundant.

- Key Locks: Key locks are the oldest of the bunch and are still widely used across Europe. Key locks have the lowest level of security as there are a mass of lock picks easily found on the internet. I would highly suggest you stay away from anything that has a single-bit key or tubular lock as they can easily be opened with a flat head screwdriver or bic pen. Just type in tubular lock pick with bic pen into youtube and you can see for yourself just how easy it is.

Steel Thickness:

A very common saying in the safe industry is the thicker the steel the better the safe. For the most part, this is very true as long as all of the other components of the safe are of good quality as well. Manufacturers will typically use a range of steel thicknesses from 14 gauge all the way to 1” thick in both the bodies and the doors. When a manufacturer doesn’t list the thickness of the steel, it is a giant red flag as the thickness is most likely as thin as possible. Many gun safe manufacturers have been changing the designs of their products to make them look more like commercial safes, but making them weaker in the process. Although these gun safes seem to offer way more protection than an average gun owner requires, they still can’t meet the lowest Underwriters Laboratories (UL) burglary performance rating of UL 687 TL-15. Most manufacturers utilize safe doors made from one layer of thin metal, 12-gauge or less, which is formed to look thick. The problem with such doors is that they can easily be pried open by robbers with everyday break-in tools. The 12-gauge safe also offers a manageable weight meaning it’s easy to move around when carried by several people, but that means it will also be easy for a couple of thieves to steal and carry it away. It is common to find gun safe doors with edge thicknesses of between 1 and 2 inches. These steel-deficient doors are mostly filled with sheetrock or partial pieces of inner door steel and although they are visibly impressive, they lack the steel to provide foundational rigidity. When looking for a good quality safe, I’d recommend no less than a 10-gauge body and a ½” plate door.

Fire Material:

Some consumers are under the mistaken impression that all steel gun safes are fireproof. Steel construction can delay fire and heat damage, but does not accord absolute fire protection in and of itself. You must buy a safe that has additional fireproofing lining its interior to fully protect your contents. Without a fireproof lining, the contents of any steel box will be damaged or destroyed as the box becomes hotter. There are two main types of fireproofing material used in the industry: sheetrock and ceramic wool.

- Sheet Rock Lining (Gypsum Drywall): Sheetrock is often considered the less efficient of the two because it has a tendency to disintegrate when it is heated. Many manufacturers who opt to use sheetrock use a material that has fiberglass embedded in it to minimize disintegration, but the problem can not be eliminated. The crumpling can cause gaps in heat protection, allowing damage to occur when heat is applied or sustained.

- Ceramic Wool: Ceramic wool offers the most consistent fire protection. Ceramic wool offers fire and heat protection up to 2300 degrees. This material is used to line melt furnaces in foundries and is sturdy. Since the average house fire never reaches 2300 and the heat is not sustained for as long as it would be in a melt furnace, you can understand the protection your contents will be afforded by ceramic wool.

For Full details regarding Fire Ratings, tests and common myths debunked, please refer to this site as the owner has put together an extremely comprehensive list explaining this complicated information: http://gunsafereviewsguy.com/articles/myths-about-gun-safe-fire-ratings/